- Irrigation

- Fencing Supplies

- Bobcat Equipment

- Case IH

- Big Tex Trailers

- Tractors & Equipment

- Yanmar

- Bush Hog Attachments

- Finishing Mowers

- Rotary Cutters

- Boom Mowers & Crop Flails

- Construction

- Landscape

- Blades

- BBX Series Box Blades

- SBX Series Box Blades

- RBX Box Blades

- MBX Series Box Blades

- Roll Over Rear Mnt Box Blade

- 35 Series Rear Mounted Blades

- 50 Series Rear Mounted Blades

- 70 Series Rear Mounted Blade

- 91 Series Rear Mounted Blade

- 100 Series Rear Mounted Blades

- 141 Rear Mounted Blade

- 160 Series Rear Mounted Blade

- 181 Rear Mounted Blade

- 225 Series Rear Mounted Blades

- 300 Series Rear Mounted Blades

- Cultipackers

- Graders

- Rakes

- Pulverizers

- Core Plug Aerators

- Spreaders

- Chippers

- Log Splitters

- Blades

- Snow Equipment

- Tillage

- Hay Tools

- Compact Implements

- UTV Implements

- Quicke Loaders

- Mahindra

- Kioti

- Deutz Fahr

- CLAAS

- Lane Shark

- Bad Boy Mowers

- Outdoor Lighting

- Contact

- Iron Bull Trailers

ESP-LXD Series

50-200 Station Two-Wire Decoder Commercial Controller

The ESP-LXD controller has been designed to maintain the look, feel and ease of programming of the ESP-LXME controller but with an interface to a two-wire path for decoder-based irrigation. The ESP-LXD controller can manage up to 50 stations but can easily be expanded for use with up to 200 stations. Flow Management is also built into every ESP-LXD controller.

Controller Features

- 50-station capability standard expandable to 200 stations with optional ESPLXD-SM75 modules

- Four available sensor inputs (one wired plus up to three decoder managed) with override switch

- Five flow sensors supported

- Supported decoders: FD-101TURF, FD-102TURF, FD-202TURF, FD-401TURF, FD-601TURF

- Supports SD-210TURF sensor decoders (flow sensing and weather sensor support) and LSP-1 line surge protectors (one per 500 feet of two-wire path required)

- Central Control capable with Rain Bird IQ Communications Cartridges and software (see pg. 102)

- Advanced Features From Cycle+Soak™ to Contractor Default Program™, the ESP-LXD offers innovative features proven to cut installation expenses, troubleshooting time and water use

- Program backup and barcode decoder address entry with the optional PBCLXD

- Six user-selectable languages

- Removable front panel is programmable under battery power

- Plastic, locking, UV resistant, wall-mount case, Optional Metal and Stainless Steel Case & Pedestal

- Compatible with Rain Bird Landscape Irrigation and Maintenance Remote - Flow Smart Module™ factory installed or field upgradable

- Plastic, locking, UV resistant, wall-mount case, Optional Metal and Stainless Steel Case & Pedestal

Water Management Features

- Cycle+Soak™ by station

- Rain Delay

- Calendar Day Off

- Programmable Delay Between Stations by program

- Master Valve programmable by station

- Sensor programmable by station

- Program & Monthly Seasonal Adjust

Diagnostic Features

- Programming prompts

- Alarm light with external case lens

- Electronic circuit breaker

- Program review

- Variable test program

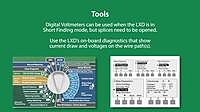

- Two-wire diagnostics to simplify and expedite troubleshooting

Operating Specifications

- Station timing: 0 min to 12 hrs

- Program level and global Monthly Seasonal Adjust; 0% to 300% (16 hrs maximum station run time)

- 4 independent programs (ABCD); ABC programs stack, ABCD overlap

- 8 start times per program

- Program Day Cycles include Custom days of the week, Odd, Odd no 31st, Even, and Cyclical dates

- Manual station, program, test program

Certifications

- UL, CE, CUL, C-Tick

Upgrade Options

- LXMM metal wall-mount case

- LXMM-PED metal pedestal

- IQ-NCC Network Communication Cartridge

- ESP-LXD-SM75 75-station module

- PBC-LXD Programming Backup Cartridge

Electrical Specifications

- Input required: 120 VAC ± 10%, 60Hz (International models: 230 VAC ± 10%, 50Hz; Australian Models: 240 VAC ± 10%, 50Hz)

- Power back-up: Lithium coin-cell battery maintains time and date while nonvolatile memory maintains the schedule

- Multi-valve station capacity: up to 2 solenoid valves per station; simultaneous operation of up to eight solenoids and/or master valves

Dimensions (W x H x D)

- 14.32” x 12.69” x 5.50” (36.4 x 32.2 x 14.0 cm)

Why is the Alarm light on the controller front panel illuminated?

Turn dial to Auto and press Alarm button to view Alarm messages.

- Alarm message: Program will not auto run. Turn dial to Test All Stations / Check System. Select Program Summary to view missing programming information.

- Alarm message: Short Detect Mode. Turn dial to Test All Stations / Check System and select 2-Wire Diagnostics.

- Alarm message: No Decoder Module. Check module. Remove and reseat module.

- Alarm message: Flow Alarm. Turn dial to Flow Smart Module - Module Status and select View Flow Alarms to view flow alarms. Select Clear Flow Alarms to clear flow alarms.

- Alarm message: Duplicate Decoder Address. Turn dial to Setup Wizards, select decoder with duplicate address and change to the correct address.

Why does the controller report that the 2-Wire Path is Off?

Turn dial to Off. Select 2-Wire Path button and press On.

When I program station run times, why does the screen say “No Decoder Address”?

Turn dial to Setup Wizards and select Station Setup. Complete the setup wizard, entering a decoder address for each station.

One of my four 2-wire paths has been cut/damaged. How do I continue using the valves on my other 2-wire paths while I fix the cut/damaged 2-wire path?

Disconnect the damaged 2-wire path from the decoder module terminal strip and leave the other 2-wire paths connected.

The controller reports the Short Detect Mode is on due to a short on one of my 2-wire paths. How do I figure out which of my 2-wire paths has the short?

Disconnect all the 2-wire paths. The controller will exit the Short Finding Mode. Reconnect one 2-wire path at a time and monitor the controller display. When you add the 2-wire path that is shorted, the controller will automatically turn on the Short Finding Mode.

Why is the lower light on a decoder module(s) not illuminated?

The Decoder Module has detected a 2-wire path short and is in Short-Finding Mode. Turn dial to Test All Stations / Check System and select 2-Wire Diagnostics.

The controller reports that a weather sensor is preventing or pausing watering. How can I determine the status of my weather sensors?

Turn dial to Test All Stations / Check System. Select Weather Sensor Status to see the status of all Weather Sensors.

I need to repair a valve on my system but I have a Normally Open Master Valve. How do I turn of the Master Valve?

Turn dial to Off. MV Off follow directions to manually close the Normally Open Master Valve.

Why are valves operating on the wrong dates/times?

- Date/time is not set correctly. Turn dial to Set Current Date, Set Current Time and set current date/time.

- Unknown Start Days/Times have been entered. Turn dial to Test All Stations / Check System and select Program Review. Review the controller programming and remove any unwanted Start Days/Times.

- A Program Water Window has delayed watering. Turn dial to Test All Stations / Check System and select Program Review. Review Programs. Change Program Water Window to allow all full program run time.

Why can't the controller turn on the valve(s)?

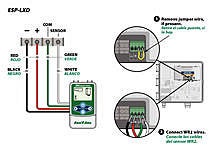

- Controller may not be wired correctly to the decoder or the decoder to the valve. Turn dial to Test All Stations / Check System and select 2-Wire Diagnostics to test decoders, valve wires and solenoid.

- 2-Wire Path may be damaged/disconnected. Turn dial to Test All Stations / Check System and select 2-Wire Diagnostics to test decoders.

- Decoder address may not be correct. Turn dial to Test All Stations / Check System and select 2-Wire Diagnostics to test decoders.

Hours

| Mon-Fri | 8 am - 5 pm |

| Sat | See Branch for Hours |

| Sun | Closed |

Bobcat Lake Oconee

1000 Bobcat Dr

Greensboro, GA 30642