- Irrigation

- Fencing Supplies

- Bobcat Equipment

- Big Tex Trailers

- Tractors & Equipment

- Yanmar

- Bush Hog Attachments

- Finishing Mowers

- Rotary Cutters

- Boom Mowers & Crop Flails

- Construction

- Landscape

- Blades

- BBX Series Box Blades

- SBX Series Box Blades

- RBX Box Blades

- MBX Series Box Blades

- Roll Over Rear Mnt Box Blade

- 35 Series Rear Mounted Blades

- 50 Series Rear Mounted Blades

- 70 Series Rear Mounted Blade

- 91 Series Rear Mounted Blade

- 100 Series Rear Mounted Blades

- 141 Rear Mounted Blade

- 160 Series Rear Mounted Blade

- 181 Rear Mounted Blade

- 225 Series Rear Mounted Blades

- 300 Series Rear Mounted Blades

- Cultipackers

- Graders

- Rakes

- Pulverizers

- Core Plug Aerators

- Spreaders

- Chippers

- Log Splitters

- Blades

- Snow Equipment

- Tillage

- Hay Tools

- Compact Implements

- UTV Implements

- Quicke Loaders

- Mahindra

- Intimidator Utility Vehicles

- Kioti

- Deutz Fahr

- CLAAS

- Lane Shark

- Husqvarna

- Bad Boy Mowers

- Outdoor Lighting

- Iron Bull Trailers

- Contact

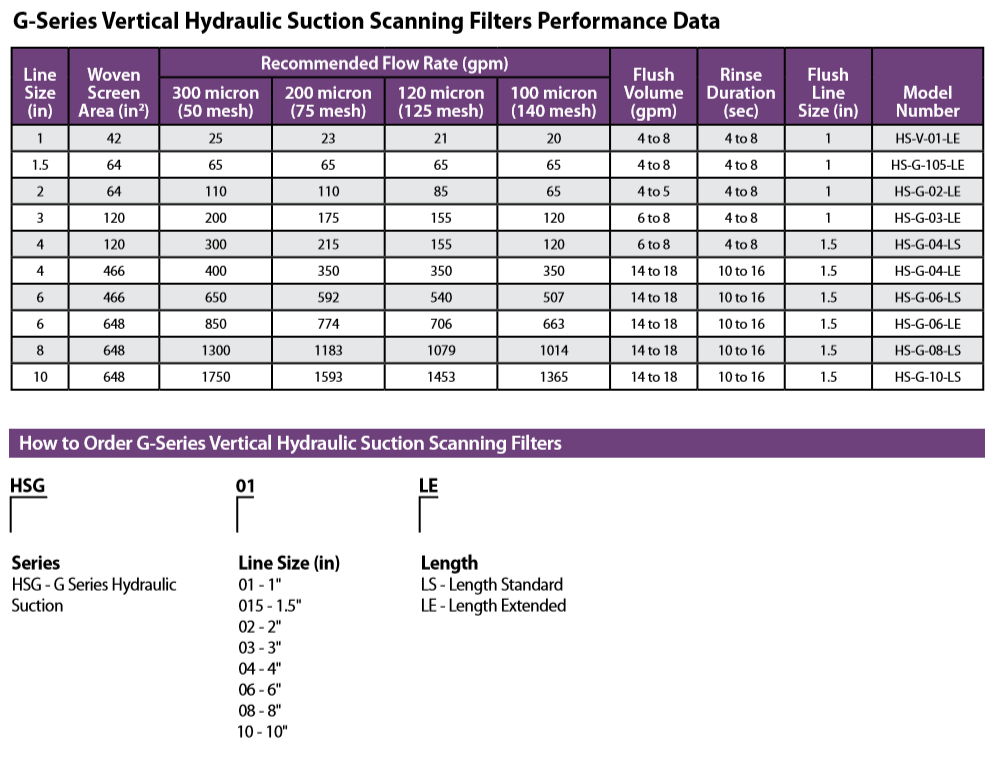

“G-Series” Hydraulic Suction Scanning Screen Filters

Home “G-Series” Hydraulic Suction Scanning Screen Filters

G Series Hydraulic Suction Scanning Filter

Economy and value with lower backwash volumes

Rain Bird’s “G-Series” Hydraulic Suction Scanning Screen Filter provides worry free medium-flow rate filtered water quality. Powered by source line water pressure, the filter’s backwashing system produces a concentrated high velocity and low volume reverse water flow to systematically clean the screen of any entrapped contaminants.

Operation

Dirty water enters the inlet (1), where it enters the fine screen (2). The water passes through the screen from the inside to the out (3). The solids accumulate on the inner surface of the screen creating a pressure differential across the screen. Once the pressure differential reaches a preset value, a rinse cycle is activated and the Rain Bird supplied control system opens the rinse valve (4) to drain. As a result, the pressure drops in the hydraulic motor chamber (5) and dirt collector assembly (6). The pressure drop causes water to backflush through the screen in a small concentrated area at the nozzle openings. The high velocity backwash stream pulls the dirt off the screen. The backwash water is carried through the collector and ejected out of the holes in the hydraulic motor (7). The dirt collector rotates while it moves linearly (on models with a piston assembly), ensuring the entire screen is cleaned each cycle. The process takes a matter of seconds, without interruption of system flow.Monitoring and Controls

The standard Rain Bird automatic control system consists of a microprocessor based controller, a differential pressure switch and a solenoid actuated flush valve. The differential pressure switch monitors inlet and outlet pressures and comes factory preset to 7 psi. The flush valve is activated by the controller when the differential pressure exceeds 7 psi. The filtration system is automatically monitored and controlled on elapsed time since the last cleaning cycle or pressure differential (user definable). If timed cleaning cycles are utilized, the system will automatically default to a backwash based on differential pressure if a 7 psi differential pressure is reached before the next timed cleaning cycle. Standard Rain Bird automatic controls are available for 115 VAC and are user configurable to 230 VAC, 50 / 60 Hz power.Note: “G-Series” filters integrated with a Rain Bird Pump Station utilize 115 VAC solenoids.

Construction

Rain Bird “G-Series” filters are built for years of durable, trouble-free service. The bodies of standard “G-Series” filters are made from high-grade, low-carbon steel. All exposed surfaces, both inside and out, are polyester powder coated over a zinc phosphate primer coat. All wetted components are constructed of either engineered plastics or non-corrosive metals. Standard 300 micron wire mesh screens are PVC-supported which virtually eliminates the possibility of screen collapse. All Rain Bird “G-Series” filters are also available in Stainless Steel construction, for the most demanding water quality applications.

- Powder-coated Carbon Steel single filter housing

- Omnitrol 150 AC or DC controller allowing filter to flush on differential pressure or time

- Includes hydraulic rinse valve. Inlet pressure during rinse cycle 35psi.

- Standard screen 200 micron (75 mesh). Additional options include: 300 micron (50 mesh), 120 micron (125 mesh), 100 micron (140 mesh). Specify screen rating when ordering

- Flow rates: 25 – 1750 gpm (5.7-397.5 m³/h)

- Working pressure: 35-150psi (2.4-10.3 bar)

- Maximum temperature: 210°F (98°C)

- Maximum operating pressure: 150 psi (10.3 bar)

- Minimum inlet pressure during rinse cycle: 30 psi (2.1 bar)

Hours

| Mon-Fri | 8 am - 5 pm |

| Sat | See Branch for Hours |

| Sun | Closed |

Bobcat Lake Oconee

1000 Bobcat Dr

Greensboro, GA 30642

© 2024 Shoemaker Irrigation Supply